NON-DESTRUCTIVE RENOVATION (RELINING) OF PIPES

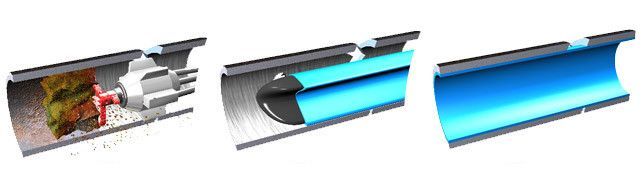

Non-destructive renovation is a pipe rehabilitation technique. It consists of repairing a pipe by applying a flexible coating from the inside. This coating is coated with a hardening epoxy or polyester resin. Once formed, it presses against the walls of the defective pipe until it is saturated.

The coating can cover all types of sanitation, drinking water, pressure water, fire fighting, industrial effluents, in cast iron, reinforced concrete, PVC, steel or iron pipes.

This is a new non-destructive technology with a low economic impact that is very useful in renovating and rehabilitating buildings you own, bringing considerable added value by renovating pipes and drains that can be refurbished, thus doubling their life cycle and avoiding costly demolition.

This technique, which is not new, was developed in the early 1970s in London for the Thames Water Company, the metropolis' drinking water and waste water management company.

Serviziecologici srl, through its highly specialised staff, is able to provide non-invasive and non-destructive solutions that enable through hardening polymerisation, renovation of pipelines, pipes and drains.

Pull in Place technology, literally translated as ‘pull in place’, consists of renewing pipes by reconstructing them from the inside by inserting an inflatable sheath composed of a felt impregnated with epoxy resins starting from a minimum diameter of 1’ 1/2.

The product is suitable for lining sanitary and sewage drains, both black and white water, as well as downpipes.

The product can be used for complete pipe reconstruction or for partial repairs, known as spot repairs.

Contact us for free inspections and estimates.

SERVICES

- Inspection of the pipe to be repaired with a video camera, to identify the breakage.

- Cleaning, to remove roots, encrustations with compressed air and ecological material.

- Impregnation, epoxy resins are mixed and poured inside the sheath between felt and air chamber, by our specialized personnel.

- Coating, the impregnated sheath is inserted inside the pipe to be repaired, once postioned it is inflated to approximately 4 bar of pressure and the hardening is waited for which can vary depending on the temperature, length and diameter, approximately 6-8 hours.

Do you want to receive more information or a quote for NON-DESTRUCTIVE PIPING RENOVATION (RELINING) ?

REGISTERED OFFICE

Via Fieno, 3 - 20123 Milano

OPERATIONAL HEADQUARTERS

CONTACTS

+39 019 690774

+39 019 690778

serviziecologici@pcert.postecert.it